News Center

Contact Us

Information Details

The production capacity exceeds 30 million tons! Inventory of 9 new coking large-scale key projects in China

Summary:

The coking industry is an important pillar industry in the development of the national economy. With the development of large-scale blast furnaces, the demand for high-quality coke in steel mills is increasing, and coke products are developing in a diversified direction. Recently, the 9 major domestic coking projects have the latest progress, as follows:

Shanxi Linxin Coal Coking Project Officially Started

Recently, the second bid section of the 1.7 million-ton/year coking project of Shanxi Linxin Coal Coking Co., Ltd. undertaken by China Fifth Metallurgical Co., Ltd. held a grand commencement ceremony.

The project is located in Daxigou, Tangcheng Town, Anze County, Linfen City, Shanxi Province, covering an area of 20000 square meters. The project is mainly composed of coal preparation system, coking facilities (2 × 65-hole JNX3-70-2 7-meter coke oven), coke treatment system, coke oven flue gas desulfurization and denitrification system, riser waste heat utilization system, dry quenching and power generation facilities, gas purification device, water treatment system and supporting public and auxiliary facilities. After the completion of the project, it is of great significance to promote the comprehensive utilization of local coal resources, increase local fiscal revenue, and develop regional economy and circular economy.

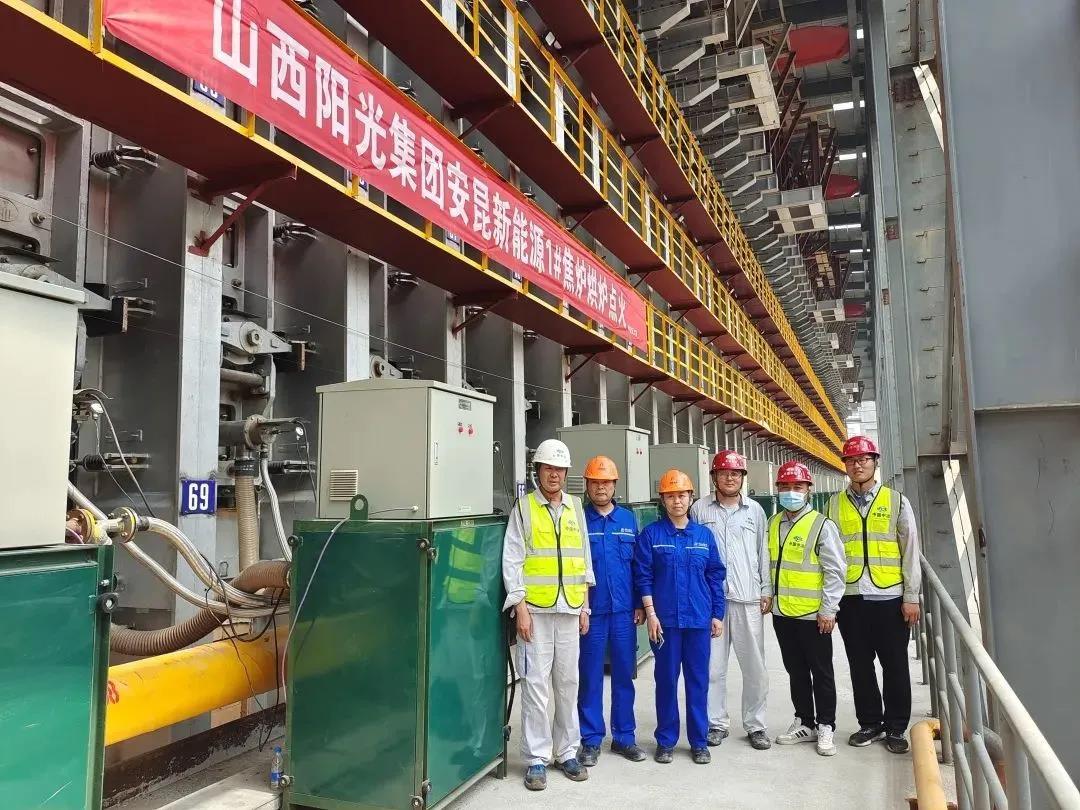

Shanxi Sunshine Ankun Coking Project Ignition Oven

At 11: 18 a.m. on July 8, the No.4 coke oven of Shanxi sunshine Ankun 3.69 million t/year 6.78 m tamping coking project designed by China metallurgical company was successfully ignited and dried.

The project uses a JNDX3-6.78-19 4X70-hole 6.78-meter single-heat tamping coke oven, which is a new generation of "2.0 version" of 6.78-meter tamping coke oven that China Metallurgical Coke Resistance has continuously summarized practical experience and continuously optimized and innovated after the first 6.78-meter tamping coke oven independently developed is completed and put into production. The project will build and put into operation four 70-hole 6.78-meter tamping coke ovens at one time, supporting two CDQ units with the largest single design capacity in China independently developed by China Metallurgical Coke Resistance, completing the replacement and upgrading of coking capacity of nearly 4 million tons. Its large construction scale and complete supporting projects also occupy an important position in the history of coking industry.

No.1 Coke Oven Masonry Capping of Chifeng Defeng Coking Project

On August 1, the No. 1 coke oven masonry of Chifeng Defeng Coking Co., Ltd., a technical renovation and upgrading project with an annual output of 3 million tons of coke, constructed by China 20th Metallurgical North Company, was successfully capped.

The project is located in the industrial zone of Xizi Town, Ningcheng County, Chifeng City, Inner Mongolia, covering an area of 1800 mu. It mainly undertakes the construction of two 65-hole tamping coke ovens, supporting chemical production recovery system, coal preparation and coke transportation system, auxiliary rooms and equipment installation works. Among them, No. 1 coke oven has complex structure, large amount of masonry, many special-shaped bricks, and the total amount of bricks used is 25000 tons.

Progress of 3 million Tons/Year Coking Project in Inner Mongolia with Investment of 22 billion Yuan

At present, the progress of the Alxa League coking project is normal. The 4# coke oven has been built to the chute and will immediately enter the carbonization room. The bottom of the 3# coke oven has been laid and the masonry of small flue has been started. The rest of the outer tube, coal preparation, coking, coking and other supporting facilities can basically meet the progress requirements of the subsequent oven. The 3 million-ton/year coking project of Alxa League Humeng Energy Industry Co., Ltd. is located in Bayin Aobao Industrial Park. The total investment of the project is 20 billion yuan, covering an area of about 4 square kilometers, and will be constructed in three phases.

The planning and construction contents of the project include an annual output of 10 million tons of heavy medium coal washing, 6 million tons of tamping coke, 1.8 million tons of methanol, 600000 tons of olefin, 200000 tons of LNG, 200000 tons of synthetic ammonia, 300000 tons of tar deep processing, 150000 tons of benzene hydrogenation project, 100000 tons of activated carbon, 50000 tons of needle coke and its supporting environmental protection, safety, fire protection and other facilities; the first phase of construction is an annual output of 5 million tons of heavy medium coal washing, 3 million tons of coking, 400000 tons of methanol and 100000 tons of liquid ammonia. The first phase of the project is expected to be completed and put into operation by the end of 2021. All planned projects will be completed and put into operation in 2025.

Lu 'an Huaneng 1.4 million Tons New Coking Project Plans to Start Joint Trial Operation in August

Lu'an Huaneng said on the investor interaction platform on August 11 that at present, the company's 1.4 million-ton/year 6.25-meter new coking project is progressing as planned and is expected to start joint trial operation this month.

Lu 'an Coking 1.4 million Tons/Year Carbonization Room Height 6.25 m Tamping Coke Oven Project Designed Annual Production Capacity 1.4 million Tons of Coke, 79200 Tons of Tar, 18900 Tons of Crude Benzene, 15800 Tons of Ammonium Sulfate and 0.603 billion Tons of Coke Oven Gas, Full Construction Started on February 28, 2020.

Shanxi Shenglong Teda 7.6-meter Top-loading Coking Project to Start

On August 12, China Fifth Metallurgical Co., Ltd. won the bid for the upgrading project of the coking technology of Shanxi Shenglong Teda New Energy Co., Ltd. with a 1.92 million-ton/year carbonization chamber height of 7.6 meters top-loading coke oven. This project is currently the top-loading coke oven with the highest carbonization chamber and the most advanced technology in China.

The project is located in Linfen City, Shanxi Province, is Zhengtai Coal Gasification and Lida Coking to replace the existing coking capacity, the advantages of resources to integrate the implementation. Coking adopts a 2 × 67-hole carbonization chamber with a height of 7.6 meters, a single-heat multi-section heating large-volume top-loading coke oven. The construction content of China Fifth Metallurgical Company mainly includes the masonry, installation and civil works of the coke oven. After the completion of the project, more than 1000 jobs can be stably provided, and the annual sales revenue is expected to reach 4.4 billion billion yuan, which is a demonstration for Linfen City to reduce backward production capacity and coking transformation and upgrading.

Henan New 1.8 million Tons Coking Project

On August 16, Henan Jinma Energy Co., Ltd. announced that in order to make full use of the 1.8 million tons of coke production capacity of the new coke oven after its commercial production, the group plans to continue to promote cooperation with Yugang Coking through its coking subsidiary to purchase an additional coke production capacity of 600,000 tons of coke per year from Yugang Coking. And part of the company's coke production capacity, that is, the annual production capacity of 1.2 million tons of coke, allocated by the Company to a coking subsidiary. The 1.8 million-ton coking project of Jinma Energy is located in the Chemical Industrial Park of Huling High-tech Industrial Development Zone in Jiyuan City. Through the relocation of the 600000-ton/year tamping coke oven of Yugang (Jiyuan) Coking Group Co., Ltd., the existing coke oven of Jinma Energy has been upgraded to effectively 1.2 million t/a capacity, a 1.8 million-ton/year coking project has been built, and the downstream industrial chain has been extended. At present, the project has been put on record in the Huling industrial agglomeration area of Jiyuan City. The project is mainly to build a 2 × 70-hole carbonization chamber with a height of 7.65m reheating top-loading coke oven, as well as supporting coal preparation, coke treatment system, dry quenching, gas purification system, coking sewage treatment system, railway special line and other production facilities and production auxiliary facilities.

Objective. This project is currently the top-loading coke oven with the highest carbonization chamber and the most advanced technology in China.

The project is located in Linfen City, Shanxi Province, is Zhengtai Coal Gasification and Lida Coking to replace the existing coking capacity, the advantages of resources to integrate the implementation. Coking adopts a 2 × 67-hole carbonization chamber with a height of 7.6 meters, a single-heat multi-section heating large-volume top-loading coke oven. The construction content of China Fifth Metallurgical Company mainly includes the masonry, installation and civil works of the coke oven. After the completion of the project, more than 1000 jobs can be stably provided, and the annual sales revenue is expected to reach 4.4 billion billion yuan, which is a demonstration for Linfen City to reduce backward production capacity and coking transformation and upgrading.

Completion of 6# Coke Oven Masonry of Shanxi Jinyan Coking Project

On the afternoon of August 23, the top masonry of the 6# coke oven for the 2.53 million-ton/year coking project of Shanxi Jinyan Energy Technology Co., Ltd. was completed and successfully passed the acceptance, marking the completion of the main masonry of the 6# coke oven on schedule.

This type of coke oven is a HT50-710 type three-stage heating top-mounted coke oven with a carbonization chamber of 7.1 meters high and 56 holes. Its main features are: double-fire exhaust gas circulation, coke oven gas and air down-regulation, air and blast furnace gas supply in sections, coke oven gas spray down, and single-heat type super-large coke oven with regenerator compartment. The second phase of the project 1. a total of 8 × 56 coke ovens. Four coke ovens in the first phase have been put into operation. The second phase of the project is under construction. All the coke ovens will form a production capacity of 5 million tons/year. The total amount of 6# coke oven refractory masonry is about 22700 tons.

Inner Mongolia black cat 10 million ton coking project is expected to be put into operation before the end of September

Recently, the first phase of the 10 million-ton coal chemical project of Inner Mongolia Black Cat Coal Chemical Industry has an annual output of 2.6 million t coking and co-production of 300000 t methanol and 80000 t synthetic ammonia by using coke oven gas has come to an end. Workers are stepping up production. It is expected that the first phase of the project will be put into operation by the end of September.

The first phase of the project has an annual output of 2.6 million t coking and co-production of 300000 t methanol and 80000 t synthetic ammonia by using coke oven gas, with a total investment of 5.524 billion billion yuan, and the overall design is ahead of the domestic level in the same period. The project started in May 2018 and the first coke oven was put into trial operation in October 2020. After the project is fully put into production, the average annual sales revenue is expected to be 4.737 billion yuan, and the average annual profit is 0.767 billion yuan. The second phase is a project with an annual output of 8.8 million t coke, 1 million t methanol, 200000 t synthetic ammonia, 200000 t benzene hydrogenation and 400000 t tar hydrogenation, with an investment of 16.16 billion yuan. After the second phase of the 1. project is fully put into operation, it can produce 9 million t of coal washing, 11.4 million t of coke, 1.3 million t of methanol, 160000 t of synthetic ammonia and 600000 t of other hydrogen supporting capacity. It is estimated that the average annual sales income is about 30 billion yuan, the average annual profit is 3.6 billion yuan, and the annual tax paid is 3.5 billion yuan, which can directly provide more than 6000 jobs and will greatly promote the rapid development of the local economy.

The coking industry is an efficient process industry that converts clean energy in my country's coal-based energy structure. In recent years, taking advantage of the supply-side structural reforms of the coal and steel industries, the environmental protection facilities of the coking industry have been continuously improved and the equipment level has been continuously upgraded. The overall development of the industry presents a positive and good development trend, which provides a solid technical and equipment guarantee for the construction of my country's modern coking industry.

Key words:

Metallurgical

Zhongke

Related News